Oil and gas production is a complex business with technical and environmental challenges

Artificial Lift in Upstream Oil and Gas Production

Artificial Lift

In this lesson, we explore the importance of artificial lift in the oil and gas industry. We will first examine the most common methods of artificial lift and where each method is best applied. We then discuss the distribution of artificial lift types in US and global operations. Finally, we’ll identify the challenges encountered when using artificial lift in horizontal wells.

As discussed in the lesson on Natural Production Drivers, during the initial stages of a well’s producing life, the fluids are kept moving as long as the natural pressure of the reservoir fluids is higher than the pressure in the wellbore. The fluids then flow into the wellbore, up the tubing string and into a stock tank. When the formation pressure becomes insufficient to lift the fluids to the surface a lot of oil is still left behind.

Can more of this oil be recovered? Yes, using what’s known as artificial lift.Every oil well and many gas wells will need artificial lift at some point in their producing life. Artificial lift refers to the use of mechanical devices, or artificial methods, to increase the flow of fluids in producing oil and gas wells. An engineer has two common methods of artificial lift to choose from – gas lift and pumping. The engineer will determine the optimum artificial lift method, depending on the well location, production rate and characteristics of the fluids being produced.

Gas Lift

Pumping

Hydraulic Pump

First, let’s discuss gas lift. Under this method, gas from an outside source is injected into the wellbore. This reduces the weight of the fluids in the wellbore and reduces the pressure needed to allow the fluids to flow up to the surface. Gas lift works for a wide range of production rates, anywhere from 50 to 50,000 barrels of oil per day. However, gas lift is not very effective or efficient if the production rate or reservoir pressure gets too low. When this occurs, other artificial lift methods must be utilized.

The second method for artificial lift involves pumping. Examples are a rod pump, an electrical submersible pump and a hydraulic pump.

Global Artificial Lift Importance

To provide some perspective, there are about a million wells utilizing artificial lift worldwide. Now let’s discuss the distribution of artificial lift types in global and US operations….

Like an ESP, a hydraulic pump is also placed in the wellbore. This type of pump puts the natural energy within the well to work to raise the fluids to the surface. One type of hydraulic pump is composed of two pistons, one above the other, which are connected by a rod that moves up and down within the pump. The production is forced against the pistons, causing pressure to lift the fluids to the surface.Though less efficient than other methods, a hydraulic pump can be used on wells with production rates ranging from 50 to 20,000 barrels of oil per day.

Rod Pump

If you have visited or lived in oil producing regions, you are already familiar with rod pumping systems. A rod pump utilizes equipment on the surface – the big metal horsehead pumping units bobbing in a field.Below the surface there is a pump at the bottom of the wellbore and a mechanical link, called a “sucker rod string”, connects the downhole pump to the horsehead at the surface.To understand how a rod pump works, think about the needle and syringe when you got your last flu shot.When you fill a syringe with medicine, you put the needle into the medicine bottle and pull up on the plunger inside the barrel of the syringe. That sucks the medicine out of the bottle and up into the barrel of the syringe.The same thing happens with a rod pump as the horsehead goes up and down.A rod pump works very efficiently on wells with low production rates, anywhere from 1 to about 3,000 barrels of oil per day.

Electrical Submersible Pump – ESP

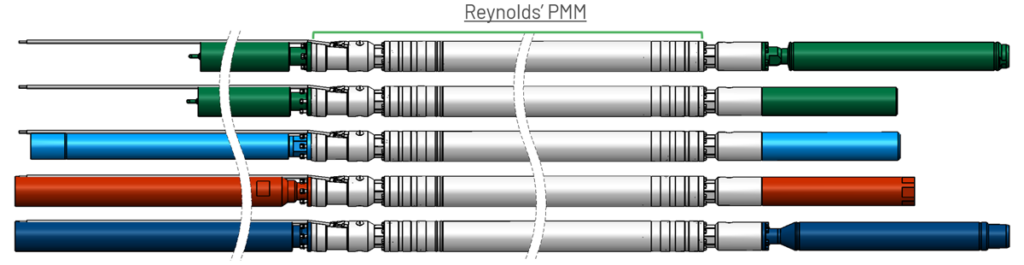

An electrical submersible pump, referred to as an ESP, involves installing a long, skinny electric motor with a protector into the wellbore. A pump is stacked onto the top of the electric motor and the unit is screwed into the bottom of the tubing string to reach the produced fluids. To control and power the pump, a well-protected electric cable goes from the downhole ESP to the surface.

ESPs are like small, downhole fluid compressors. The motor rotates a shaft in the pump that has a series of “stages” attached to it. The stages are similar to a juggler’s plates spinning atop sticks. Each stage adds centrifugal force to the fluid, increasing pressure so the fluid travels up the tubing string and out to the stock tank. An ESP can support a wide range of production rates, anywhere from 500 to 50,000 barrels of oil per day.