Wellhead Maintenance Services

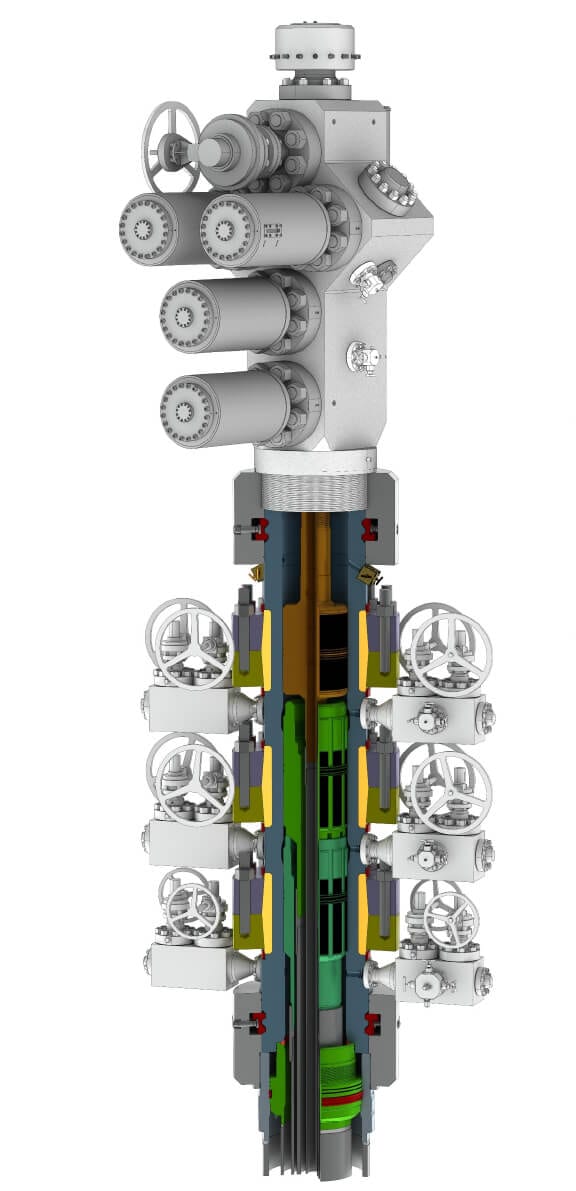

Wellhead maintenance services form a key part of OSA Energy ’s well integrity capability – from new HPHT developments, through to the mature brownfield site. This includes the routine inspection, repair and maintenance of surface wellheads, as well as the provision of pressure testing services.

Wellheads, Valves and their actuators are key assets in the oil and gas industry. Ensuring they work properly is key to hitch-free operations.

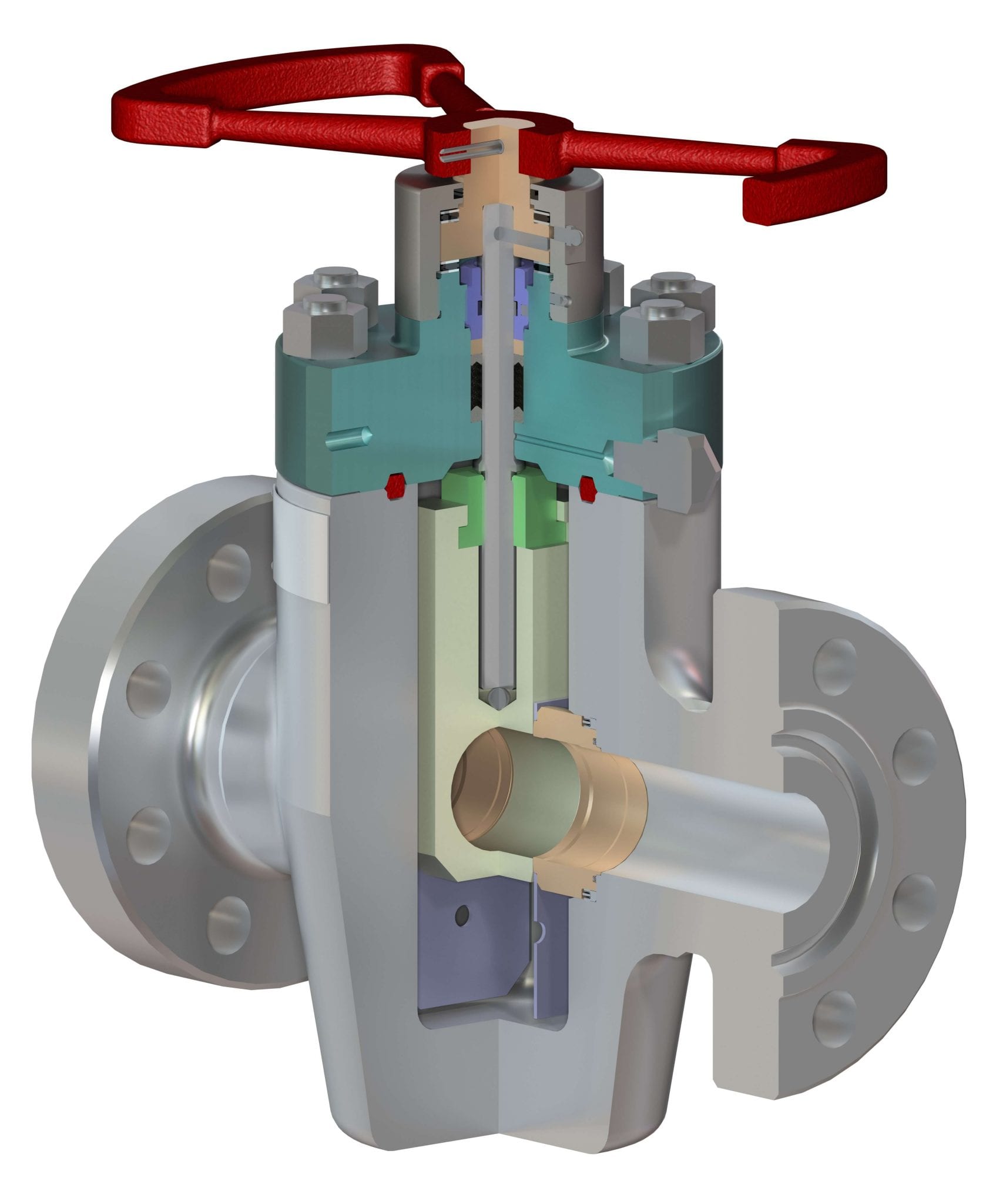

Our services include routine Wellhead Maintenance as well as Wellhead Completions. Our expertise covers various Wellheads, Chokes & Valves including Cameron, Vecto Gray, FMC & Kvaerner.

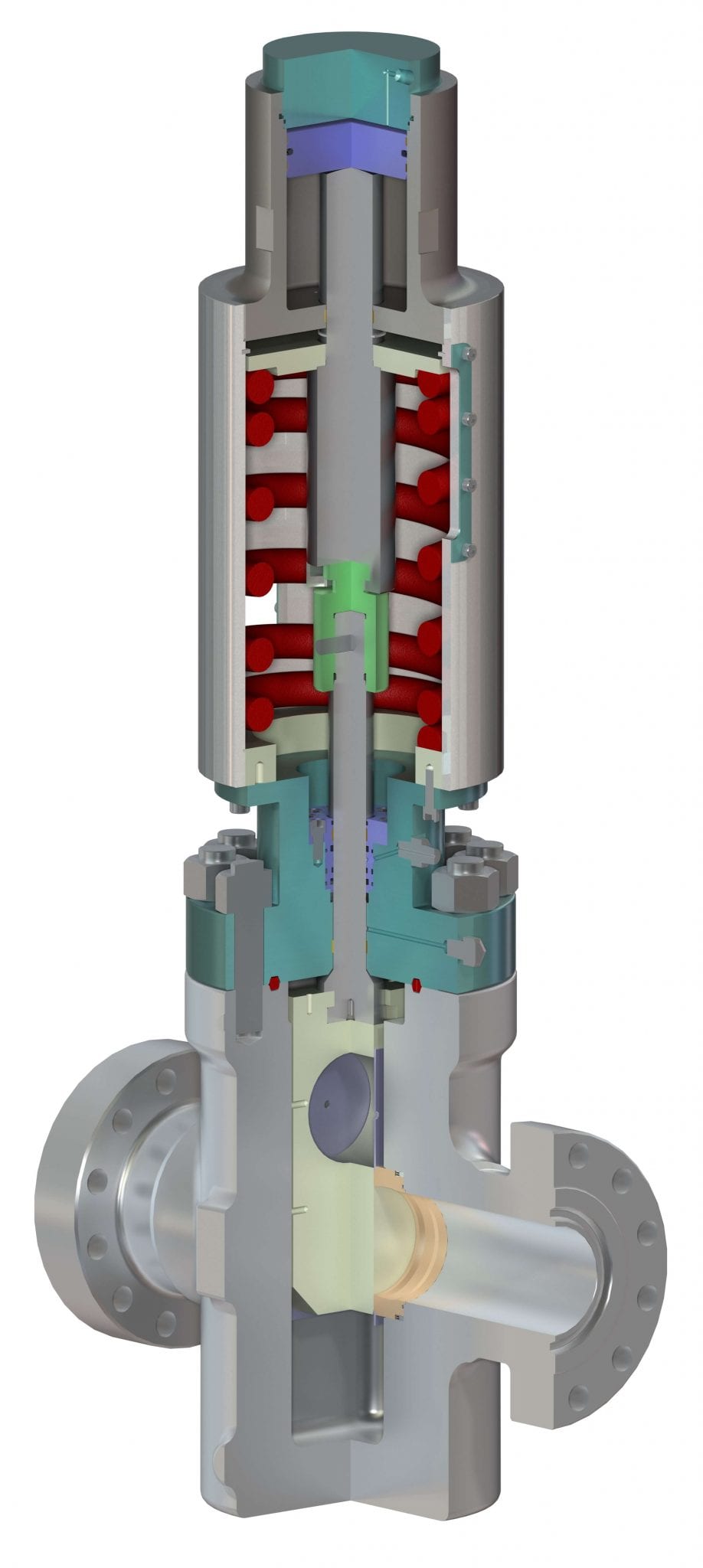

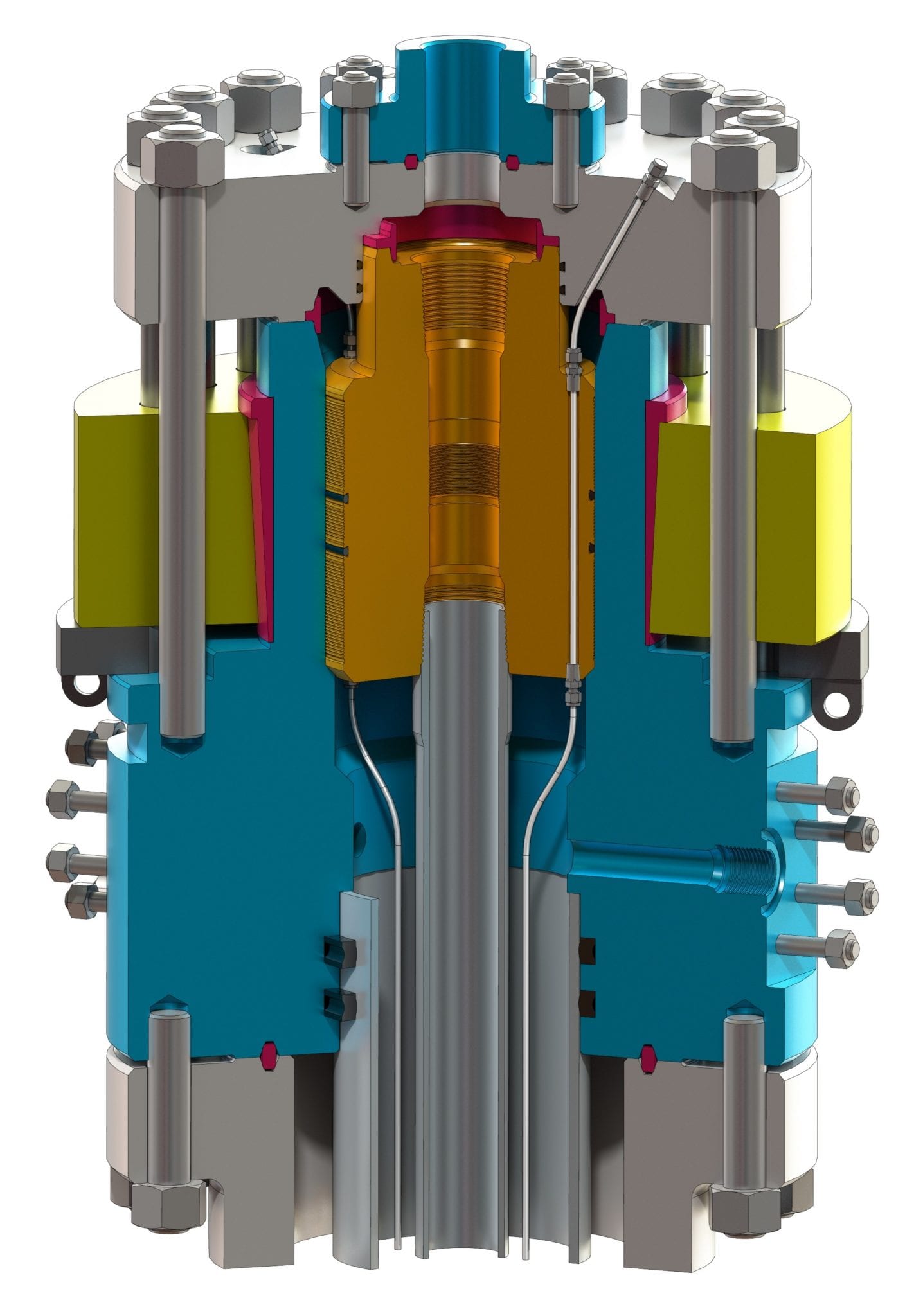

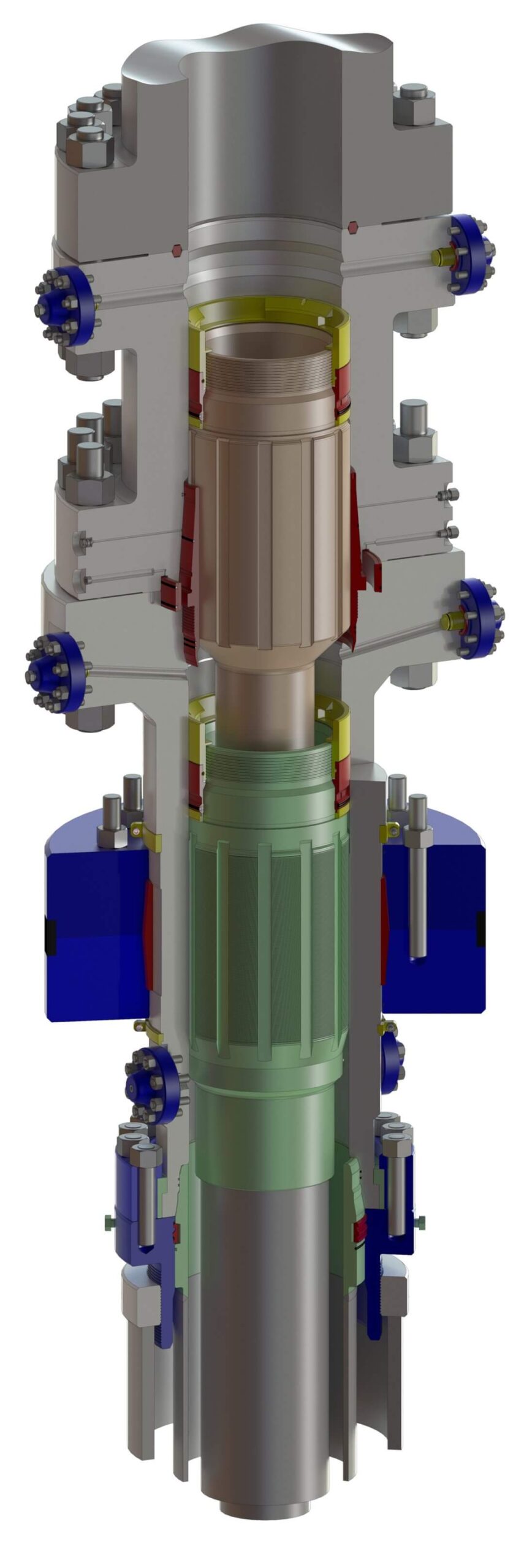

Comprehensive valve refurbishment are carried out by skilled engineers and technicians at our dedicated workshops. OSA Energy Services Limited supplies quality Wellhead systems to suit all casing size requiremnets – to full API specifications. We provide conventional stack-up wellhead systems, full bore and slim hole multi-bowl wellhead systems as well as systems for gas and oil well applications. These surface wellhead systems can be used on or offshore.

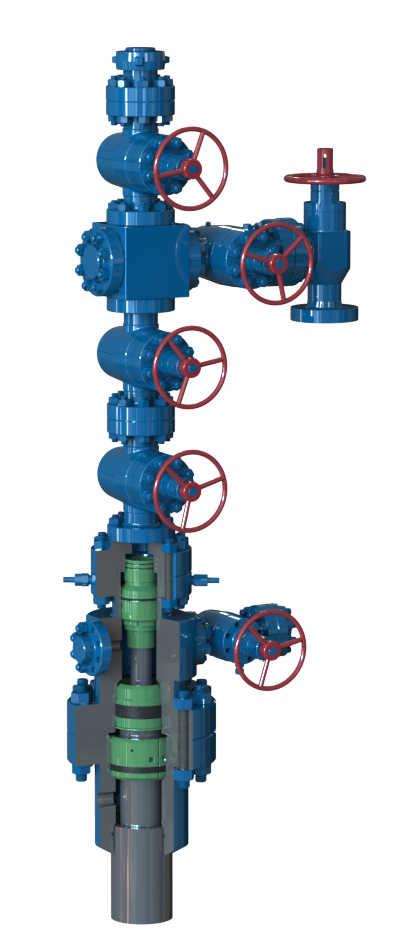

Standard Christmas Trees are manufactured in two versions as a standard production head called “Christmas Tree” as well as a compact version called “Solid Block”. In the second version gate valves are assembled directly into the production head body so that its height is lower

We can provide three different types of maintenance service including:

Preventive Maintenance

Lubrication and visual inspection of the state of wellhead valves and accessories.

Pressure tightness test and database update.

Corrosion preventions, painting of well structures.

Maintenance of actuators and replacement of limbs seals.

Maintenance work

Replacement of valve internals–Caps, seat Seal…

Hydraulic valve pressure test.

Lubrication andvisual inspection of pressure valves.

Replacement

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Hotbolting.

BPV, TWCV, VR Plug Installation.

Replacement of manual gate valves and actuators